Como escolher as lâminas certas para triturador: um guia simples

Jul 29, 2024

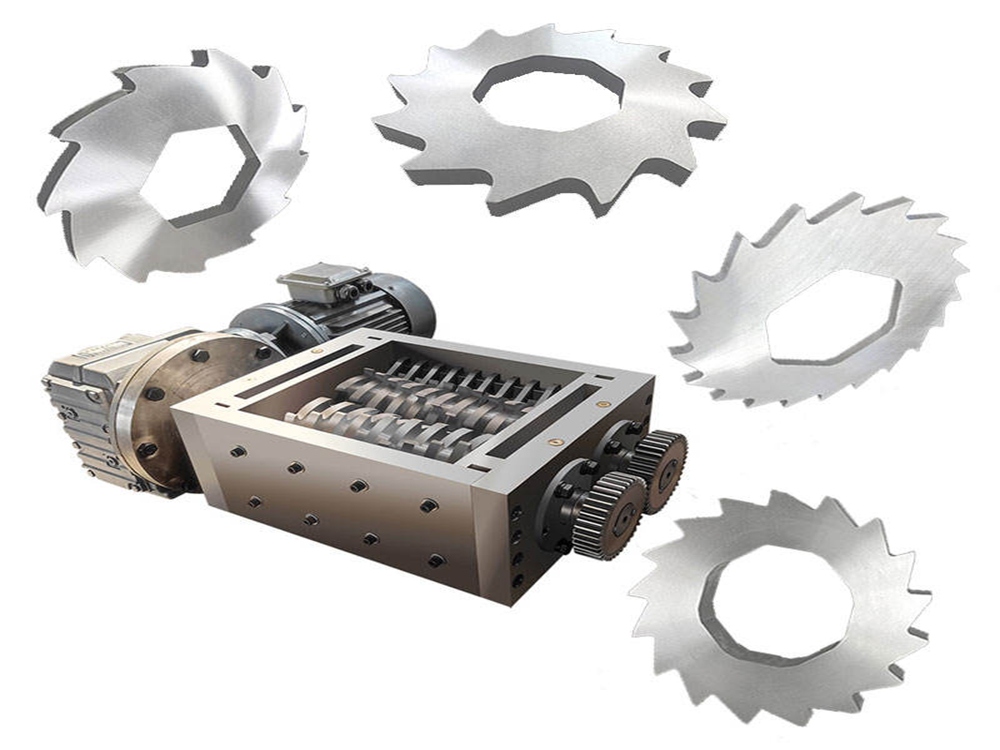

Escolher as lâminas certas para o seu triturador é muito importante. Isso afeta o desempenho e a durabilidade da máquina. Seja para triturar plástico, madeira ou metal, você precisa escolher a lâmina mais adequada para cada tarefa. Aqui está um guia simples para te ajudar nessa escolha. 1. Material das Lâminas O material da lâmina é o primeiro aspecto a considerar. Materiais diferentes funcionam melhor com diferentes tipos de trituração. Para triturar plástico: Os materiais mais comuns são o 9CrSi, o 55Si6 e o SKD-11. Esses materiais são muito duros e resistentes ao desgaste. Eles suportam plásticos com diferentes níveis de dureza. Para triturar madeira: Bons materiais incluem 9CrSi, 55Si6, SKD-11 e H13. Essas lâminas são suficientemente resistentes para triturar madeira com eficiência. Para triturar metal: O ideal é usar lâminas feitas de Cr12MoV1, H13 ou 6CrW2Si. Esses materiais são altamente resistentes ao desgaste e suportam a tensão de triturar metal. 2. Formato das Lâminas As lâminas vêm em diferentes formatos. O formato que você escolher depende do que você está triturando. Lâminas móveis: Geralmente, essas lâminas têm formato de garra. O número de dentes na lâmina é importante. Mais dentes significam que o material processado será mais fino. Mas se a lâmina tiver dentes em excesso, pode ficar menos resistente e desgastar-se mais rapidamente. Lâminas fixas: Essas lâminas ajudam a evitar que o material se enrole na máquina. Elas devem ser compatíveis com as lâminas móveis para garantir uma boa trituração. 3. Espessura das Lâminas A espessura da lâmina determina a largura do material triturado. Lâminas mais grossas produzem pedaços mais largos. Elas também são mais resistentes e duram mais. No entanto, é preciso encontrar um equilíbrio. Se a lâmina for muito grossa, pode não ser adequada para triturar em pedaços mais finos. Sempre pense no material que você está triturando e no formato que deseja obter. 4. Processo de Tratamento Térmico O tratamento térmico torna as lâminas mais resistentes e duráveis. Existem diferentes tipos de tratamento térmico, como cementação, cementação a vácuo e cementação iônica. Esses processos tornam a superfície da lâmina mais dura. Por exemplo, uma lâmina cementada pode atingir uma dureza de HRC 56~61. Isso faz com que a lâmina dure de 1,8 a 3 vezes mais do que uma lâmina que passou apenas por têmpera convencional. 5. Manutenção das Lâminas Cuidar bem das suas lâminas é muito importante. Aqui vão algumas dicas: Verifique as lâminas regularmente: Examine as bordas das lâminas. Se estiverem cegas, danificadas ou quebradas, substitua-as o mais rápido possível. Ajuste a distância entre as lâminas: Dependendo do que você estiver triturando, pode ser necessário ajustar o espaço entre as lâminas. Isso ajuda a manter a trituração eficiente e protege a máquina. Limpe as lâminas: Após o uso, limpe as lâminas para remover qualquer resíduo de material. Isso mantém as lâminas em boas condições. Conclusão Escolher as lâminas certas para o seu triturador não é difícil se você souber o que procurar. Considere o material, o formato, a espessura e o tratamento térmico das lâminas. Além disso, lembre-se de fazer a manutenção adequada das lâminas. Fazendo isso, você obterá o melhor desempenho do seu triturador e prolongará a vida útil das lâminas. Se precisar de ajuda para escolher as lâminas, consulte sempre um profissional. Ele poderá ajudá-lo a encontrar as melhores lâminas para as suas necessidades. Boa trituração!

LEIA MAIS